Tubeless Misconceptions

Tubeless wheels and tires can greatly improve the ride experience on any bicycle. The primary benefits are simply: Lower rolling resistance, better traction, and reduced likelihood of flat tires.

However, many road riders are still leery of this superior technology, and we have found that they often believe misconceptions about tubeless tires that are simply untrue. We’re here to set the record straight and get you rolling on a better setup.

MISCONCEPTION # 1 – TUBELESS TIRES ARE HARDER TO INSTALL AND MAINTAIN

FALSE! It is simply a different process than installing a tire on non-tubeless rims.

People with 10-30 years of experience installing tubed tires will struggle if they do not adapt their technique to modern tubeless-compatible rims.

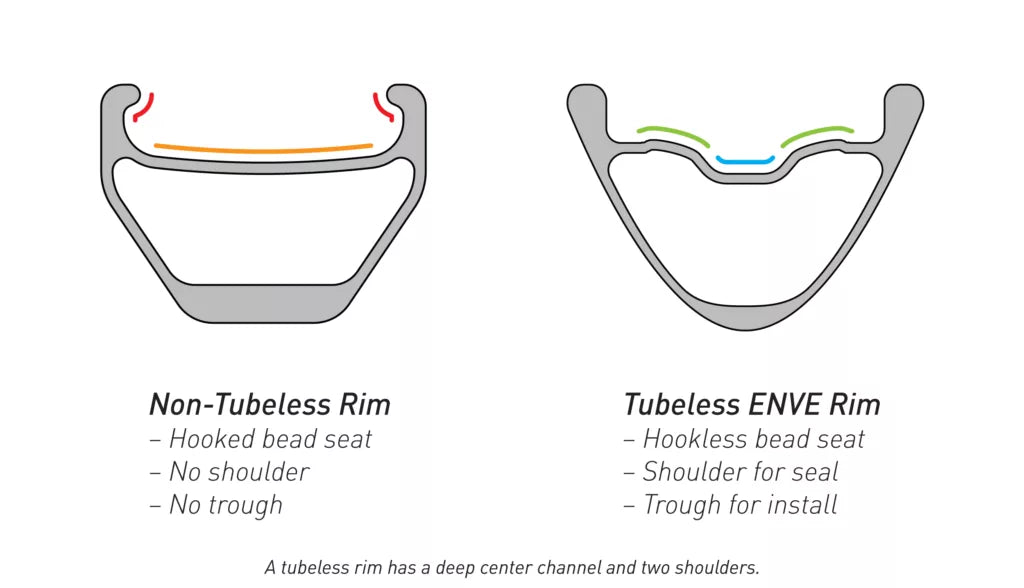

The rim’s shoulders are key: This is the surface on which the tire and rim create the air-tight seal. The center channel reduces the rim’s diameter, effectively allowing the tire to be installed. It is imperative that the tire’s bead is in that center channel when installing a tubeless tire, and the installation is finished at the valve, not the opposite.

If you don’t get the tire’s beads in the channel, you’ll fight it until your fingers are raw, and no tire lever will help you. While tire diameters will vary (even within the same model) you can often install a tire with nothing but your hands but, in some instances, a plastic tire lever is needed. The tire lever should only be required for the final few inches of bead on tighter than normal tires.

Removing a tire is the same. First, pop the tire’s bead off the rim’s bead-locking shoulder and into the rim’s center channel. Pushing the bead into the channel all the way around makes tire removal possible and quite easy with the help of a tire lever.

KEY TAKEAWAY: Tubeless tire install and removal isn’t harder, it just requires the right technique.

MISCONCEPTION #2 – YOU CANNOT USE AN INNER TUBE ON A TUBELESS WHEEL OR WITH A TUBELESS TIRE

FALSE! An inner tube can always be used in a tubeless wheel or with a tubeless tire.

While you will sacrifice rolling efficiency and flat-resistance, tubes are compatible with tubeless tires and rims, but should be used as a backup in case of a rare but unfortunate tubeless flat tire. Should you experience a flat while running a tubeless setup, you can finish your ride and get you home by simply removing the tubeless valve stem and installing an inner tube, just as you would on a non-tubeless setup.

One exception: If you are running an SES, Foundation or G Series hookless rim, you may only run innertubes with a tubeless-compatible tire. It is equally important to adhere to each rim’s maximum tire pressure rating. This ensures that the tire will remain safely seated on the rim. The ENVE SES Tires are compatible with both hooked rims and hookless rims for peace of mind regardless of the rim design. Explore the SES Tire line.

KEY TAKEAWAY: It doesn’t hurt to pack a spare tube, just in case.

MISCONCEPTION #3 – TUBELESS IS UNRELIABLE

FALSE! Tubeless, when done properly, is the pinnacle of reliability.

There are many elements to a tubeless system, and all of them must be installed properly or maintained, but that doesn’t mean the system is unreliable. Tubeless tires and wheels can last you seasons of trouble-free use without needing attention.

During initial setup, it’s important to remember that the entire system — as well as the tires — need a 24-hour period to settle and absorb sealant. Often, after first setup, both tires will go flat overnight. To combat this, a ride immediately after set-up will help spread the sealant around for an airtight setup. As with a normal tube setup, it’s still important to check air pressure before every ride. Modern tubeless ready tires are porous, and will lose anywhere from 1-5psi overnight.

After initial setup, top off your sealant, because it will be absorbed into the tire’s casing to form a seal. To ensure continued reliable use, check and top-off your sealant at regular intervals. We find that every 30-90 days is a good interval depending on where you live, and how often you ride.

KEY TAKEAWAY: Like most bike components, tubeless requires correct setup and a little routine maintenance to work correctly.

MISCONCEPTION #4 – CAN’T PINCH FLAT A TUBELESS SETUP

FALSE! While a tubeless setup is capable of reducing nearly 50% of your flats – it cannot prevent all pinch-flats.

Excessively low pressure, and a violent impact will pinch the tire between a literal rock and a hard place, possibly piercing your tire, just as it would a tube. Fortunately, sealant within the tire may fill this hole or holes. Simply spinning the wheel to put the hole closest to the ground will force sealant to this area to fix the flat.

If the pinch creates too large of a cut, sealant alone will not work, and you’ll have to resort to inserting a tube. Fortunately, as we learned previously – putting a tube in a flat tubeless system is an option.

To combat the dreaded tubeless pinch flat, wheels like the new SES road line , G23, AG25 and M Series feature anti-pinch flat technologies built into the rim. Each technology aims to dissipate energy from impacts across a larger area to prevent cutting the tire against the rim. The “Wide Hookless Bead” is a lightweight technology for road, gravel, and mountain bike applications and reduces tubeless pinch flats by 50%.

KEY TAKEAWAY: Tubeless isn’t invincible, so make sure you’re running the correct tire pressure for your terrain.

MISCONCEPTION #5 – RUNNING TUBELESS MEANS I CAN RUN LOWER TIRE PRESSURE

FALSE! It isn’t about running lower pressure, it is about riding the correct pressure, and knowing it’ll be efficient, comfortable, and grippy.

One of the greatest benefits of running a tubeless setup, besides removing friction-inducing inner-tubes, is the ability to maximize comfort, traction – and ultimately, confidence – with proper tire pressure. While it’s still possible to pinch flat a tubeless setup (see above), it’s far less likely than if you were running tubes.

Over the years, many riders have run too much tire pressure in order to prevent pinch flats. Put another way, they would rather reduce traction, and sacrifice efficiency than get a pinch-flat. We can’t blame them. Nothing is more inefficient than stopping on the side of the road or trail to fix a flat tire.

Tubeless allows riders to run the right tire pressure. The right tire pressure maximizes traction, comfort, and rolling efficiency. To help riders consistently achieve proper tire pressure, we’ve created the ENVE Air Pressure Station and a page all about tire pressure where you can view charts that will help you find your proper tire pressure.

KEY TAKEAWAY: A better tire system means no compromises when you choose the right pressure for your ride.

Sure, there are a handful of misconceptions surrounding tubeless and proper setup. However, each of these misconceptions can be remedied with some education about how tubeless works and some hands-on experience.

On the road and trail, there are no misconceptions – tubeless technology delivers the ultimate ride experience.